What is a Dust Test Chamber?

A Dust Test Chamber, also known as a Sand & Dust Test Chamber, is a precision laboratory instrument designed to simulate natural wind-blown sand and dust climates. It recreates the harsh dusty environments that products might encounter in the real world by precisely controlling parameters such as dust concentration (using materials like silicate cement, talcum powder), wind speed, temperature, and humidity within a sealed testing space. Its core purpose is to evaluate a product’s sealing integrity and resistance to corrosion.

What Products is it Used For?

Virtually any product that might be exposed to outdoor or dusty environments requires dust testing:

Automotive Industry: Headlights, dashboards, connectors, seals, air intake systems.

Electronics & Appliances: Smartphones, smartwatches, outdoor surveillance cameras, drones, EV charging stations.

Military & Aerospace: Missile guidance systems, communication equipment, military vehicle components.

Lighting Industry: Outdoor luminaires, street lights, landscape lighting.

Home Appliances: Robotic vacuum cleaners, AC outdoor units.

What Standards Does It Comply With?

The design and testing procedures of dust test chambers strictly adhere to various international and national standards to ensure authoritative and comparable results. The most common standards include:

IEC 60529: This is the most widely recognized standard, defining IP (Ingress Protection) ratings. Specifically, IP5X (Dust Protected) and IP6X (Dust Tight) tests must be performed using a dust test chamber.

GB/T 4208: The Chinese national standard, equivalent to IEC 60529.

ISO 20653: Road vehicles – Degrees of protection (IP code), for electrical equipment in vehicles.

MIL-STD-810G: U.S. Military Standard, Method 510.5 is dedicated to sand and dust environments, with extremely rigorous requirements for vehicles and military equipment.

ASTM D4214: Standard from the American Society for Testing and Materials.

How is the Machine Calibrated for Accuracy?

Regular calibration is essential to guarantee the accuracy and reliability of test results. Calibration is typically performed by accredited third-party metrology organizations and focuses on several key areas:

Dust Concentration Calibration: Using a precision balance to weigh the dust collected over a specific period, calculating and adjusting the dust concentration inside the chamber to meet standard requirements.

Wind Speed Calibration: Using a calibrated anemometer to measure wind speed at multiple points inside the chamber, ensuring it is uniform and stable at the set value (e.g., ≥1.5m/s as required by many standards).

Temperature Calibration: Placing a standard temperature sensor inside the workspace and comparing the chamber’s display reading to the actual temperature, then correcting any deviations.

Pressure Difference Calibration: For IP5X and IP6X tests, a specific negative pressure must be maintained between the inside and outside of the chamber. Calibrating this pressure differential using a micro-manometer is a critical step.

Sieve Mesh Inspection: Verifying that the wire mesh sieve used for dispensing dust conforms to the specified mesh size, ensuring the correct particle size distribution of the dust.

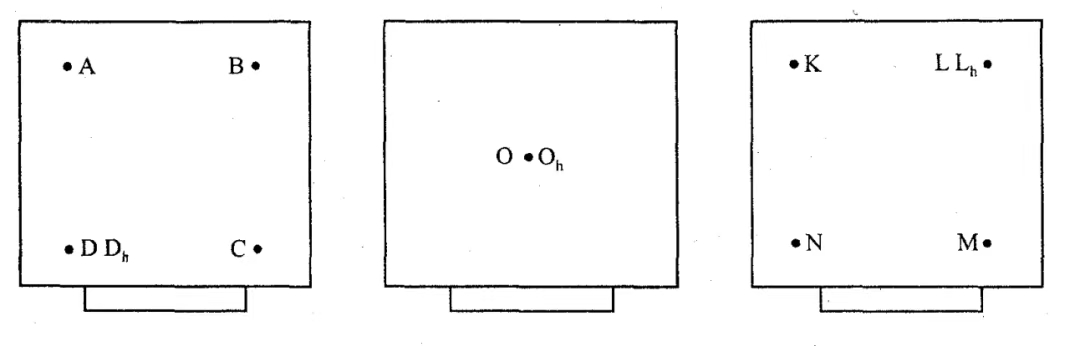

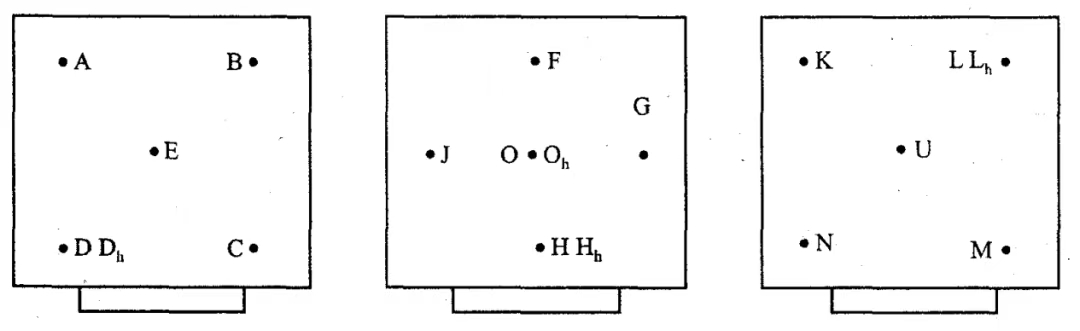

a) The working space of the dust test equipment is divided into upper, middle, and lower layers. The middle layer passes through the geometric center A of the working space. Measurement points are located in the upper, middle, and lower layers.

b) The measurement points are denoted by the symbols O, A, B, C, D, E, F, G, H, J, K, L, M, N.

c) Relative humidity measurement points are denoted by the symbols Oh, Dh, Hh, Lh.

d) The number and placement positions of the wind speed and dust concentration measurement points are exactly the same as those for the temperature measurement points.

e) Measurement points E, O, Oh, U are located at the geometric centers of the upper, middle, and lower layers, respectively. The distance from other measurement points to the inner wall of the equipment is 1/6 of the length of the respective side, but the maximum distance shall not be greater than 500 mm, and the minimum distance shall not be less than 50 mm.

f) When the volume of the dust test equipment is less than or equal to 2 m³, there are 9 temperature measurement points and [number intended here] relative humidity measurement points. The placement positions are as shown in the figure below: Schematic diagram of the placement of temperature and humidity measurement points when the dust test chamber volume is less than or equal to 2 m³.

g) When the volume of the dust test chamber is greater than 2 m³, there are 15 temperature measurement points and 4 relative humidity measurement points. The placement positions are as shown in the schematic diagram of the placement of temperature and humidity measurement points for dust test equipment with a volume greater than 2 m³.

h) When the volume of the dust test equipment is less than 0.05 m³ or greater than 50 m³, the number of measurement points may be appropriately reduced or increased. Depending on the needs of testing and calibration, additional measurements may be added at suspected points within the working space of the dust test equipment.