Standards Compliant:

Textiles: ASTM D1424, DIN 53862, EN ISO 13937-1, ISO 4674-2, ISO 9290, M & S P29, NEXT 17, NF G07-149, GB / T 3917.1 Textiles – Tear properties of textiles Part 1 Determination of the impact of pendulum hammer test method.

Paper: GB / T 455, APPITA P 400, ASTM D 689, BS 4468, CSA D9, DIN 53128, EN 21974, ISO 1974, JIS P 8116, PAPTAC D9, SCAN P11, TAPPI T414, UNI 6444

Plastics: GB / T 11999, ASTM D1922, ISO 6383-2, JIS K 7128-2, NF T54 141

Instrument Characteristics:

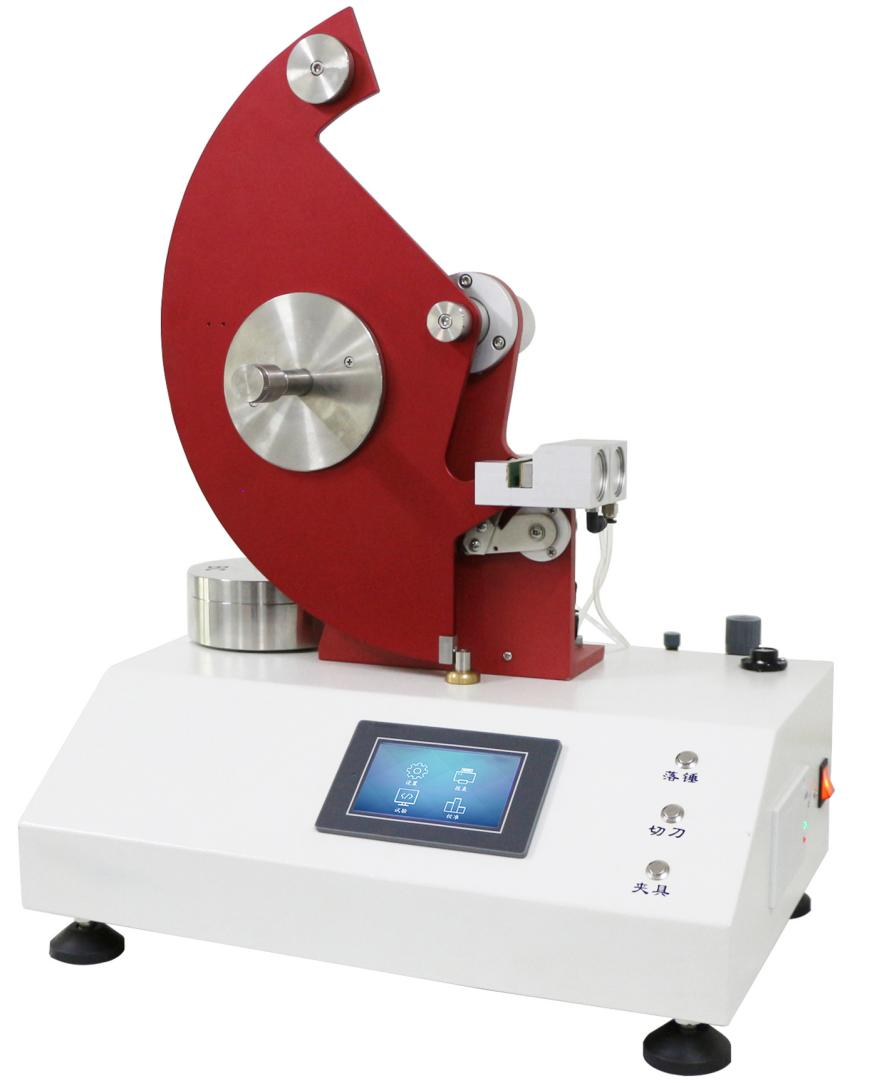

Advanced calculation method (kinetic energy method calculation) to ensure accurate testing and good repeatability.

Color touch screen control system, Chinese and English operation interface, built-in thermal printer, print data reports.

All data and statistical results can be freely checked in the host.

The test unit can be selected and automatically converted between N, gf, cN and lbf to meet different standard requirements.

Pneumatic sample clamping and pendulum release ensure consistent clamping force and reduce operation steps.

Automatic sample cutting reduces operation steps.

USB interface, professional computer analysis software, computer data storage (obtained national software copyright registration certificate).

Technical Parameters:

|

Standard Weights (A-C) |

0~16N (A hammer), 0~32N (B hammer), 0~64N (C hammer) |

|

Test Accuracy |

≤±0.2%F·S |

|

Tear Length |

43mm |

|

Cut Length |

20±0.2mm |

|

Sample Clamping |

Pneumatic |

|

Compressed Air |

600~800kPa |

|

Dimensions |

480×420×470mm |

|

Weight |

55kg |

|

Power Supply |

AC220V 50Hz 100W |

© Dongguan Zhongli Instrument Technology Co., Ltd.

Leave your inquiry, we will provide you with quality products and services!

Please fill out the form below to request a quote or to request more information about us. please be as detailed as possible in your message, and we will get back to you as soon as possible with a response. we’re ready to start working on your new project, contact us now to get started.