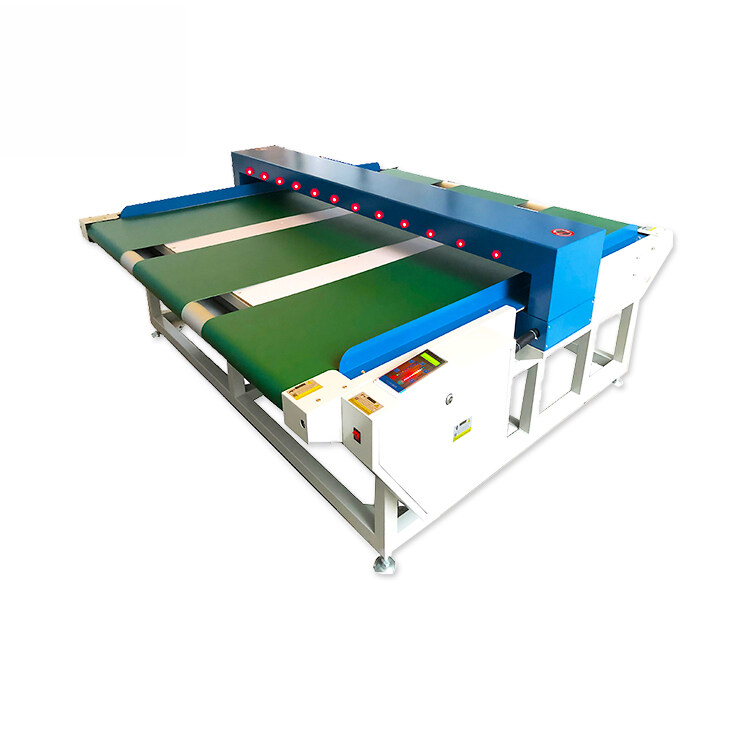

This Machine is an ordinary needle detector designed with anti-jamming digital circuit and magnetic induction principle. It is mainly used to detect ferromagnetic metals such as needles and iron filings in textile products. Can effectively eliminate: electromagnetic waves such as ceiling fans, sewing machines, sealing machines.

This Machine is an ordinary needle detector designed with anti-jamming digital circuit and magnetic induction principle. It is mainly used to detect ferromagnetic metals such as needles and iron filings in textile products. Can effectively eliminate: electromagnetic waves such as ceiling fans, sewing machines, sealing machines.

Applicable Places:

Check broken needles: women’s wear, men’s wear, student uniforms, overalls, baby products, knitwear, underwear, socks, fabrics, non-woven fabrics, embroidery, towels, bath towels, carpets, gloves, toys, handicrafts, etc.

Through the inspection needle: hardware button, metal zipper, Japanese word buckle, bead chain, brooch and other clothing handbags metal accessories over the needle machine.

|

Technical Parameter:(Can Custom) |

|||||||

|

Detection Width |

Detection height |

Detection standard |

Conveying speed |

Power Supply |

Power |

Weight |

Volume (L×W×H) |

|

600mm |

120mm |

Fe ø≥1.0mm |

25~30 |

220V |

100W |

180KG |

1650×960×900 |

|

Description |

The sensitivity is determined by the detection height (ie channel or gantry) to determine the highest detection accuracy. The higher the gantry, the lower the sensitivity. The above corresponding height and detection standard are the detection results in the empty machine state; the detection channel height and width can be customized according to requirements! |

||||||

Custom Reference:

|

Detection Width |

1000mm~5000mm Customized on demand |

|

Detection Height |

120-150-200-250mm on demand |

|

Testing Standard |

Fe Φ ≥0.8-1.0-1.2-1.5-2.0mm |

|

Conveying Speed |

25~30m/min |

|

Power Supply |

220V 50-60Hz |

|

Power |

120W |

|

Weight |

500~1000KG |

|

Volume (Length × Width × Height) |

2200 × 2300 × 900mm (subject to actual custom specifications) |

Functional features.

▪ DN8500 digital patented movement circuit;

▪ Super anti-interference computer chip integrated circuit, dual-way sensor, equivalent to and better than the traditional dual-probe needle detector;

▪ All function keys are touch key switch, with a total of 200 levels of adjustment of 100 levels each of high and low sensitivity;

▪ Eight-point part display the exact location of broken needles function; with counting function, distinguish through good and bad products;

▪ Alarm function for the sound, LED light indication, automatic backward / stop three;

▪ Special protection circuit, ten minutes without the object to be inspected through the automatic stop; function set in the main power on, without starting the motor before completion;

▪ With A/B/C/D (semi-automatic/thin material/thick material/automatic) mode switching function, adapt to different products of the inspection operation;

▪ When detecting broken needle, iron objects, sound and light two kinds of alarm mode, and stop backward to the starting point, and automatically run again;

▪ High sensitivity, detection gantry height of 12cm, detection of fine iron chips 0.8mm in diameter, nine point test method does not miss detection.

© Dongguan Zhongli Instrument Technology Co., Ltd.

Leave your inquiry, we will provide you with quality products and services!

Please fill out the form below to request a quote or to request more information about us. please be as detailed as possible in your message, and we will get back to you as soon as possible with a response. we’re ready to start working on your new project, contact us now to get started.