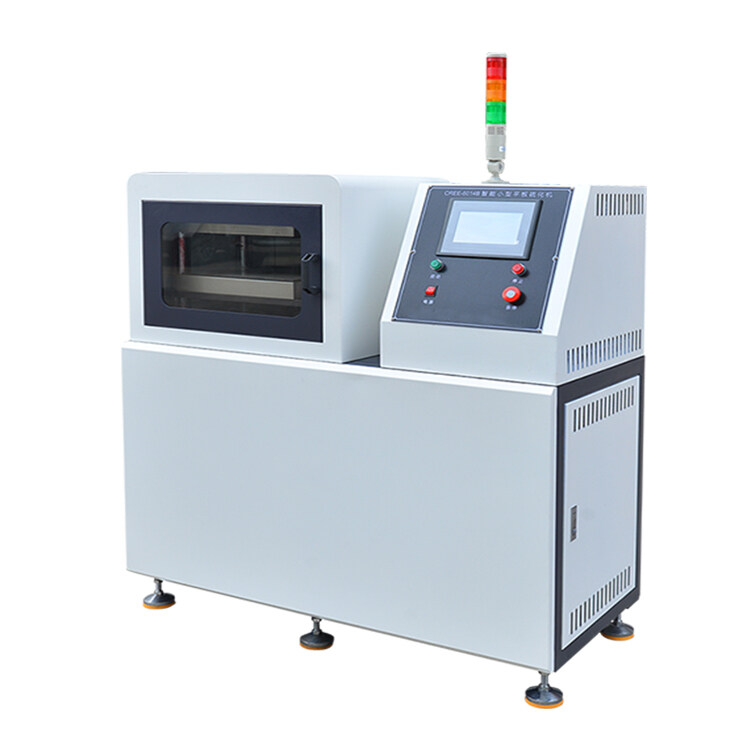

This series of Hydraulic Press Testers are used as the main equipment for pressing and molding various rubber model products and non-model products. They can also be used to press various thermosetting plastics and foamed rubber and plastic products. They have independent power mechanisms and electrical systems, and are centrally controlled by buttons. The working pressure and heating temperature can be adjusted within a certain range. This machine is available in manual and semi-automatic versions.

Overview:

This series of Hydraulic Press Testers are used as the main equipment for pressing and molding various rubber model products and non-model products. They can also be used to press various thermosetting plastics and foamed rubber and plastic products. They have independent power mechanisms and electrical systems, and are centrally controlled by buttons. The working pressure and heating temperature can be adjusted within a certain range. This machine is available in manual and semi-automatic versions.

Equipment Parameters:

|

Model |

ZL-3022D |

|

Pressure Capacity |

30T |

|

Pressure Gauge |

Dual-node pressure adjustable, pressure adjustment accuracy 10% |

|

Plate Size (mm metric) |

250*250/300*300/350*350/400*400/450*450/500*500/600*600【mm】 |

|

Hot Plate Material |

Imported high temperature resistant steel plate, surface carburization quenching, special treatment for fast heat conduction, pressure parallelism without deformation, wear resistance. |

|

Plate Hardness |

50~60HRC |

|

Plate Flatness |

0.03mm |

|

Plate Flatness |

≤0.03mm |

|

Plate Parallelism |

≤0.16mm |

|

Temperature range [select one according to the quotation] |

Normal temperature -250℃ [customizable maximum temperature 500 degrees] |

|

Temperature Uniformity |

2.5℃ [The larger the pressure plate, the higher the temperature and the worse the temperature uniformity] |

|

Temperature Controller |

Precision module, with PLC touch screen control, touch screen built-in display, numerical display. |

|

Temperature Control Method |

The temperature control mainboard is precisely controlled, self-tuning and matched with high-precision sensors, and the temperature control display accuracy is: ±0.1℃. |

|

Timer |

The touch screen displays the time range from 0.1S to 99min to 9.9hr. |

|

Heater |

Heating mold built-in cylindrical type [Configure different power packaging platen temperature uniformity according to the platen area, not the same power] |

|

Heating Time |

Normal temperature ~ 160℃ takes about 15 minutes |

|

Two Hot Plates |

The hot plate can be set to control the temperature |

|

Heating Method |

Electric heating |

|

Cooling Method |

Natural cooling/water cooling |

|

Hydraulic System |

Adopting CREE.6 hydraulic flow closed-loop control system, the oil pump drives high-performance electro-hydraulic and cooperates with high-precision resistance-free oil cylinder piston to execute equal rate control mode, with automatic pressure compensation function. One-time pressurization, automatic pressure replenishment, strong load force, smooth lifting and lowering; automatic pressurization, pressure maintenance, and pressure relief. |

|

Cylinder Stroke |

Max 150mm [customizable] |

|

Cylinder Speed |

11mm/s |

|

Pressure Gauge |

0~200kg/sq.cm |

|

Mold Opening Method |

Fully automatic rise and fall (with manual and automatic dual functions) |

|

Safety Device |

Safety cover, safety door. |

|

Number of Safety Devices |

4 |

|

Mold Frame [optional] |

Customized |

|

Main Unit Size |

(W×D×H)1200×750×1650 mm |

|

Power Supply Voltage |

3 ∮ ,AC380V |

|

Total Weight |

≈780kg |

Features:

①The main body of the equipment adopts seamless welding technology.

②The exterior adopts high-temperature paint to prevent rust.

③The upper and lower heating plates adopt tool steel quenching treatment, which is rust-proof, wear-resistant and high hardness.

④Parallelism of upper and lower heating plates 0.1mm

⑤Temperature uniformity within 1 degree

⑥Pressure adjustable

⑦The factory develops program controller.

⑧Taiwan Delta PLC touch screen operation is more convenient, faster and more beautiful

⑨The program can control the experiment and obtain more specific and more realistic experimental data.

© Dongguan Zhongli Instrument Technology Co., Ltd.

Leave your inquiry, we will provide you with quality products and services!

Please fill out the form below to request a quote or to request more information about us. please be as detailed as possible in your message, and we will get back to you as soon as possible with a response. we’re ready to start working on your new project, contact us now to get started.