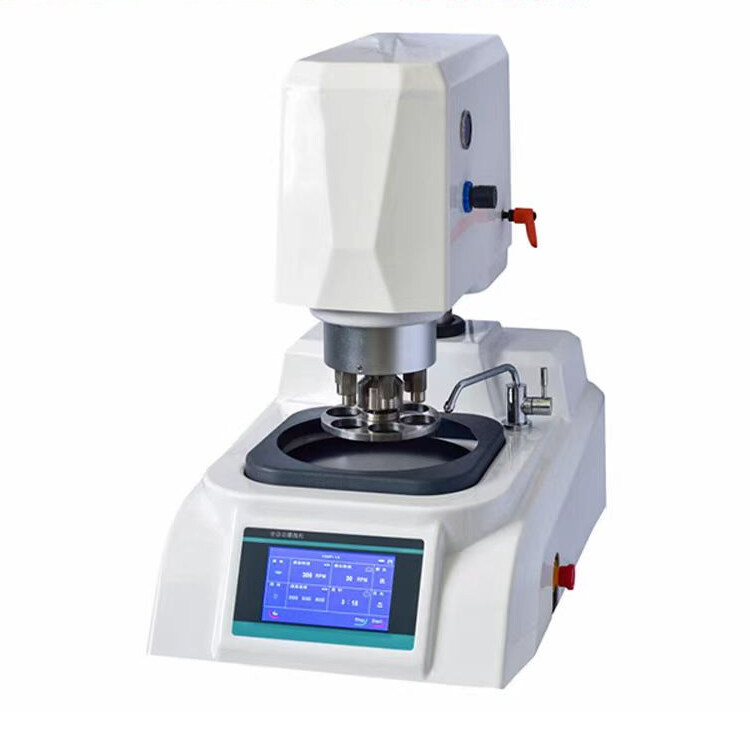

Pre-grinding, grinding and polishing in one single-disk automatic grinding and polishing machine. It adopts single-chip technology controlled by touch screen, the grinding and polishing disk is driven by DC brushless motor and driven by V-belt, and the grinding head is driven by stepping motor and driven by synchronous belt. It has the features of smooth rotation, low noise, long service life, safety and reliability, etc.; according to the user’s needs, it can self-adjust the rotational speed of the grinding head and grinding and polishing disk, and it can set its own pressure and customize its own time to adapt to the different needs. It has its own lighting system, which is convenient for taking and placing specimens; it has its own cooling device, which can be used to cool the specimens when grinding, so as to prevent the destruction of metallurgical organization due to overheating of specimens, and it is the ideal choice for metallurgical sampling equipment in factories, scientific research units and laboratories of colleges and universities.

Product Overview

Pre-grinding, grinding and polishing in one single-disk automatic grinding and polishing machine. It adopts single-chip technology controlled by touch screen, the grinding and polishing disk is driven by DC brushless motor and driven by V-belt, and the grinding head is driven by stepping motor and driven by synchronous belt. It has the features of smooth rotation, low noise, long service life, safety and reliability, etc.; according to the user’s needs, it can self-adjust the rotational speed of the grinding head and grinding and polishing disk, and it can set its own pressure and customize its own time to adapt to the different needs. It has its own lighting system, which is convenient for taking and placing specimens; it has its own cooling device, which can be used to cool the specimens when grinding, so as to prevent the destruction of metallurgical organization due to overheating of specimens, and it is the ideal choice for metallurgical sampling equipment in factories, scientific research units and laboratories of colleges and universities.

The main functions and features

III.Technical parameters:

|

Model |

ZL-2514 |

|

Number of grinding discs |

1 |

|

Grinding and polishing disc diameter |

254mm |

|

Grinding and polishing disc speed |

Stepless speed regulation 100-1000r/min Fourth gear speed regulation 300 500 800 1000r/min

|

|

Grinding and polishing disc rotation direction |

forward and reverse |

|

Power of grinding motor |

1.1KW |

|

Direction of rotation of the grinding head |

clockwise |

|

Rotating speed of grinding head |

0—120r/min |

|

Grinding head motor |

Stepper motor 200W |

|

Grinding head locking mode |

Manual (with optional automatic) |

|

Timer adjustable time |

0-99min |

|

Pressure adjustment mode |

mechanical regulator |

|

Pressurizing method |

Single point pneumatic pressurization |

|

Pressurizing pressure |

0-0.5Mpa (commonly used 0.2-0.3Mpa) |

|

Specimen clamping quantity |

6 |

|

Specimen thickness |

8-22mm (can be customized) |

|

Specimen clamping specification |

)Standard Ф30, (Ф22 Ф30 Ф45 optional, special specifications can be customized) |

|

Power supply |

220V 50Hz |

|

Total power |

1.8kw |

|

Overall Dimension |

475*660*710mm |

|

Weight of specimen |

80kg |

IV.lConfiguration list:

|

Name |

Quantity |

Remarks |

|

Grinding disk Φ254 |

1 |

Installed on the equipment |

|

Magnetic disk |

1 |

Installed on the equipment |

|

Water retaining ring |

1 |

Installed on the equipment |

|

Anti-sticking disk |

2 |

Φ250mm |

|

400 grit sandpaper with adhesive |

4 |

Φ250mm |

|

8800 mesh sandpaper with adhesive |

4 |

Φ250mm |

|

1200 Grit Gummed Sandpaper |

4 |

Φ250mm |

|

Gummed Polishing Cloth |

4 |

Φ250mm |

|

Inlet hose |

1 |

6-point connector |

|

Outlet hose |

1 |

Φ32 |

|

Technical Documents |

1 copy of the product manual, 1 copy of the product certificate of conformity. |

|

© Dongguan Zhongli Instrument Technology Co., Ltd.

Leave your inquiry, we will provide you with quality products and services!

Please fill out the form below to request a quote or to request more information about us. please be as detailed as possible in your message, and we will get back to you as soon as possible with a response. we’re ready to start working on your new project, contact us now to get started.