1.Product description:

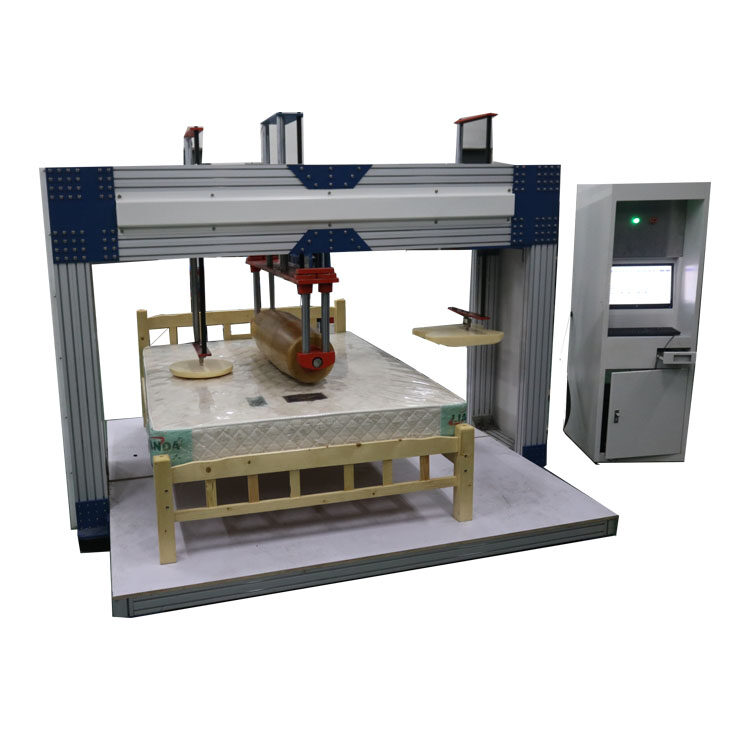

Suitable for a variety of mattress durability tests, vertical downward force tests, and height measurement test, mattress comprehensive tester.

2.Meet the standards:

QB/T 1952.2-2011, ASTM F 1566 and EN 1957 requirements.

3.Product use:

The mattress rolling durability test is a machine designed to simulate the constant rolling during human sleep, and the durability of the mattress edge. It is mainly to test the durability of the edge of the mattress to meet the requirements of various mattress manufacturers and standards. It is used to determine the quality and service life of mattresses, and strictly abide by the requirements of national standards for mechanical testing. Suitable for strong spring mattresses, ordinary spring mattresses, foam mattresses, brown fiber elastic mattresses, etc.

4.Loading test:

The rolling durability testing machine was used for the test. Before the test, the roller device was adjusted to be in the center line of the loading area, and the driving device applied force in the horizontal direction. Do reciprocating motion in the direction, and each loading includes one reciprocation. During the test, an appropriate method should be used to fix the mattress to prevent the mattress from moving.

5.Technical parameters:

|

1. Controller |

full computer control |

|

2 .Hexagonal drum length |

36±3in (915±75mm) |

|

3 .Hexagonal drum weight |

240±10Lb (109±4, 5kg) |

|

4 .Hexagonal roller side-to-side distance |

17±1in (430±25mm) |

|

5 .Length of round drum |

1000mm |

|

6 .Round drum weight |

1400N |

|

7 .Diameter of round drum |

300mm |

|

8 .Rolling speed |

20±2 times/min |

|

9 .The accuracy of the force measuring device is not less than 1%, the accuracy of the size device is not less than 1mm, and the position deviation of the loading block is ±5mm |

|

|

10. Control method |

full computer control |

|

11 .Monitoring method |

buzzer alarm, indicator light flashes |

|

12 .Running accuracy |

±0.2mm |

|

13 .Roller material |

electrical wood material |

|

14.Motor |

Japan Panasonic servo motor |

|

15.Appearance |

paint treatment and aluminum alloy structure anode treatment |

|

16.Test table material |

stainless steel |

|

17.The height of the test table from the ground |

500mm |

|

18.Test mattress size |

2200*2000mm (length*width) |

|

19.Height test |

place the mattress horizontally on the flat plate, and pass the circular pad at the measuring position to (100±20)At a speed of mm/min, a force of 4N is applied vertically downward. At this time, the distance between the lower surface of the circular block and the flat plate is measured as the store height HD of the mattress. |

|

20.Power supply and power |

AC2201V 50HZ single-phase. About 2.2KW |

6.Test device:

The rolling durability test is mainly composed of a roller and a driving device. The roller can move relatively horizontally on the surface of the mattress. The surface of the roller should be hard, smooth, and free from scratches and other surface defects. The durability testing machine should be able to apply a force of 1400±7N to the mattress surface through the roller under static conditions, and the roller can rotate freely around its central axis and maintain balance. During the rotation, the roller is attached to the surface of the mattress, cyclically rolling and applying force in the specified area, and can float up and down the rolling deformation of the mattress on the surface of the mattress. The loading frequency should be 16±2 times/min. .

7.The main technical specifications of the test pad height:

|

1. Measuring pad |

the measuring surface is a flat and smooth rigid cylinder. |

|

2. Measure the diameter of the pad |

100mm, and the chamfer is R10. |

|

3. The force application speed of the pad |

100±20mm/min. |

|

4.Vertical downward force |

apply 4N force, at this time, the distance between the lower surface of the circular cushion block and the flat plate is the height of the mattress. |

|

5.Measuring height |

The initial height of the mattress is measured after 100 and 29,900 durability tests. |

8.Instrument features:

|

1. Data protection |

automatic saving after power failure (data can be automatically saved after power failure). |

|

2.Touch screen control |

data display, powerful and intelligent. |

|

3.The edge durability test part adopts a cantilevered mechanical structure and uses pneumatic loading transmission parts, which improves the mechanical strength and rigidity of the whole machine, increases the service life and the accuracy of the detection data, and effectively reduces the running noise. |

|

|

4.Perfect structure design with low energy and low noise. |

|

© Dongguan Zhongli Instrument Technology Co., Ltd.

Leave your inquiry, we will provide you with quality products and services!

Please fill out the form below to request a quote or to request more information about us. please be as detailed as possible in your message, and we will get back to you as soon as possible with a response. we’re ready to start working on your new project, contact us now to get started.