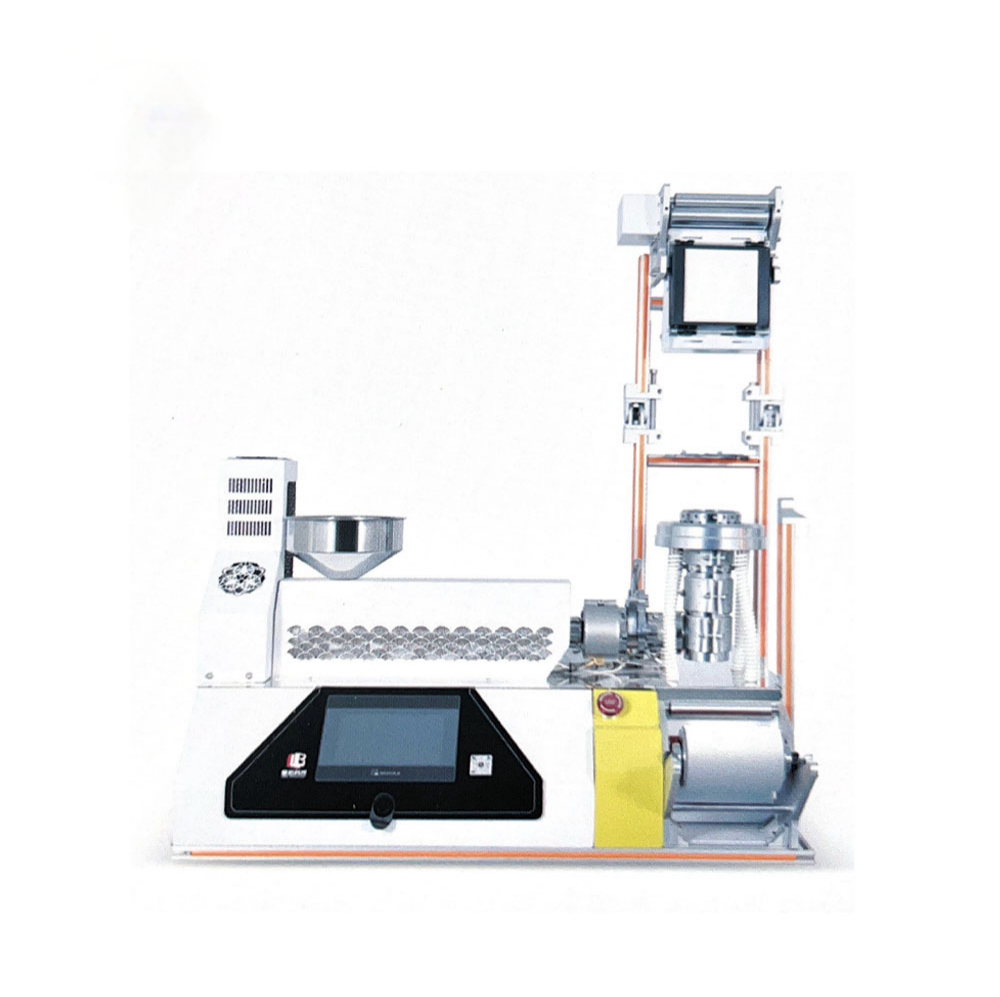

I.Equipment Overview:

ZW-703 desktop laboratory blown film machine consists of one 16 single-screw extruder, single-layer blown film die head blown film auxiliary machine and PLC centralized control system. Plastic raw material is melted and plasticized and extruded by one extruder, and then blown into film with independently adjustable width, thickness and layer ratio by sleeve-type die head.

II.Description:

The product integrates the company’s precision extrusion technology and blown film molding technology, with convenient control and adjustment of stable performance, wide applicability of raw materials, as well as less material, small footprint, etc., especially suitable for the laboratory environment, is the enterprise and universities, research institutes, research and development of new materials, new formulas, new processes, a powerful tool.

III.Primary Configuration:

|

Screw |

|||

|

Feed section longitudinal grooving, making the extrusion volume increased, while the raw material in the barrel plasticizing time is long, better plasticizing effect. Low rotational speed can reduce the wear and tear of barrel and screw, and prolong the service life. |

|||

|

Screw diameter(mm) |

Φ16(mm) |

||

|

Processing technology |

blown film special screw, tempering, nitriding treatment; spraying alloy |

||

|

Nitriding depth |

﹥0.6 mm |

||

|

Nitriding hardness |

≥960 |

||

|

RV40 Turbo Reducer |

RV40 |

||

|

Screw L/D ratio |

30:1 |

||

|

Screw material |

Alloy steel |

||

|

Screw speed (r/min) |

110 |

||

|

Screen changer |

Manual duplex |

||

|

Heating ring |

Ordinary heating ring |

||

|

Die Head |

|||

|

Features of the die head:The die head is an internal single-layer runner structure, designed for degradation material products, the mold runners are uniformly distributed, no dead ends, improving the fluidity of the melt in the mold, effectively solving the problem of material retention in the mold, so that the molded film products have a good surface finish and transparency. |

|||

|

Diameter of mold head |

Φ70(mm) |

||

|

Die opening clearance |

0.6 |

||

|

Diameter of wind ring |

180mm |

||

|

Main Motor |

600 servo 1.98N |

||

|

24V DC fan |

100W |

||

|

Suitable material |

PBAT/PLA/PE |

||

|

Tractor Frame Section |

|||

|

Turbo gear motor integrated machine |

100W |

||

|

Traction roller length |

150mm |

||

|

Traction roller diameter |

Φ40 |

||

|

Traction pressure roller length |

150mm |

||

|

Winding Section |

|||

|

Single Winding |

Single Winding |

||

|

Winding method |

Backrest rewinding |

||

|

Thickness of rolled wallboard |

10Mm |

||

|

Roller Diameter |

Φ50 |

||

|

Machine Size |

|||

|

Length×Width×Height |

800×500×1000 |

||

|

Capacity |

2 kg/h |

||

|

Distribution Box Section |

Branding |

||

|

Host servo |

600W1.9N |

— |

|

|

Traction DC speed control motor |

100W |

— |

|

|

Temperature Control |

5-way temperature control module |

AISET |

|

|

Solid State Relay |

5-way |

Omron |

|

|

Relay |

— |

CHNT |

|

|

Air switch |

— |

CHNT |

|

|

Push button switch |

— |

CHNT |

|

|

Control method |

4.3-inch human-machine interface |

— |

|

© Dongguan Zhongli Instrument Technology Co., Ltd.

Leave your inquiry, we will provide you with quality products and services!

Please fill out the form below to request a quote or to request more information about us. please be as detailed as possible in your message, and we will get back to you as soon as possible with a response. we’re ready to start working on your new project, contact us now to get started.